Technology

Basic Characteristics of Triporous™

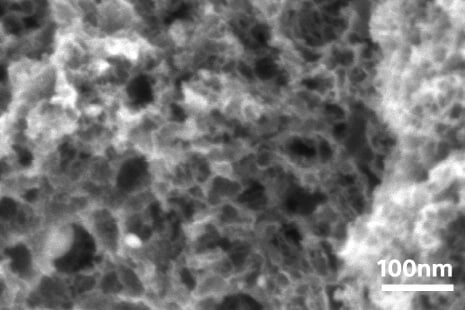

Triporous

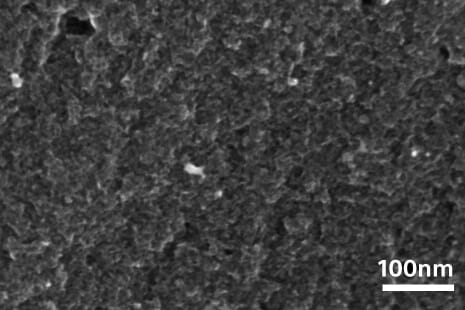

Conventional Activated Carbon

Enlarged Image of Triporous

Enlarged Image of Conventional Activated Carbon

SEM photographs taken by Toshiyuki Yokoi Laboratory of Tokyo Institute of Technology

Triporous™ contains a mix of 2-nm micropores, 2 to 50-nm mesopores, and approximately 1-μm macropores, all in enormous quantities.

In contrast, conventional activated carbon is essentially made up of micropores.

For this reason, Triporous easily adsorbs large substances, such as high-molecular-weight organic compounds and viruses,

which are difficult to adsorb with conventional activated carbon.

Compared to activated carbon, Triporous also possesses characteristics such as superior adsorption speed and high chemical loading capacity.

[A unique porous structure, created in a manufacturing process developed by Sony]

In order to remove large amount of silica accumulated between the cells of the husks,

the first step of Triporous manufacturing is to carbonize the rice husks under un inert atmosphere.

Next, the silica is “etched” (eliminated) to form large macropores, and then mesopores and micropores are developed in an activation process

(high-temperature process that uses water vapor).

With this manufacturing process invented by Sony, Triporous realizes its unique structure featuring micro, meso, and macropores.

Sony has acquired numerous and various patents relating to Triporous materials and applied technologies.

Quick Adsorption

ammonia gas, responsible for odors, adsorbed 6 times faster by Triporous compared to conventional activated carbon*1

Conventional activated carbon has a low volume of macropores, so it is difficult for substances to pass through it,

and adsorption consequently requires considerable time.

On the other hand, the large macropores and mesopores in Triporous serve as pathways for substances,

and intraparticle diffusion is fast, enabling high-speed adsorption.

For example, one assessment of adsorption speed for ammonia, the gas responsible for odors,

found that Triporous adsorbs odors approximately six times faster than conventional activated carbon.

Adsorption is fast in the liquid phase too, so in a water purifier filter, Triporous has the potential to remove impurities very rapidly.

- *1 Activated carbon made from coconut shell.

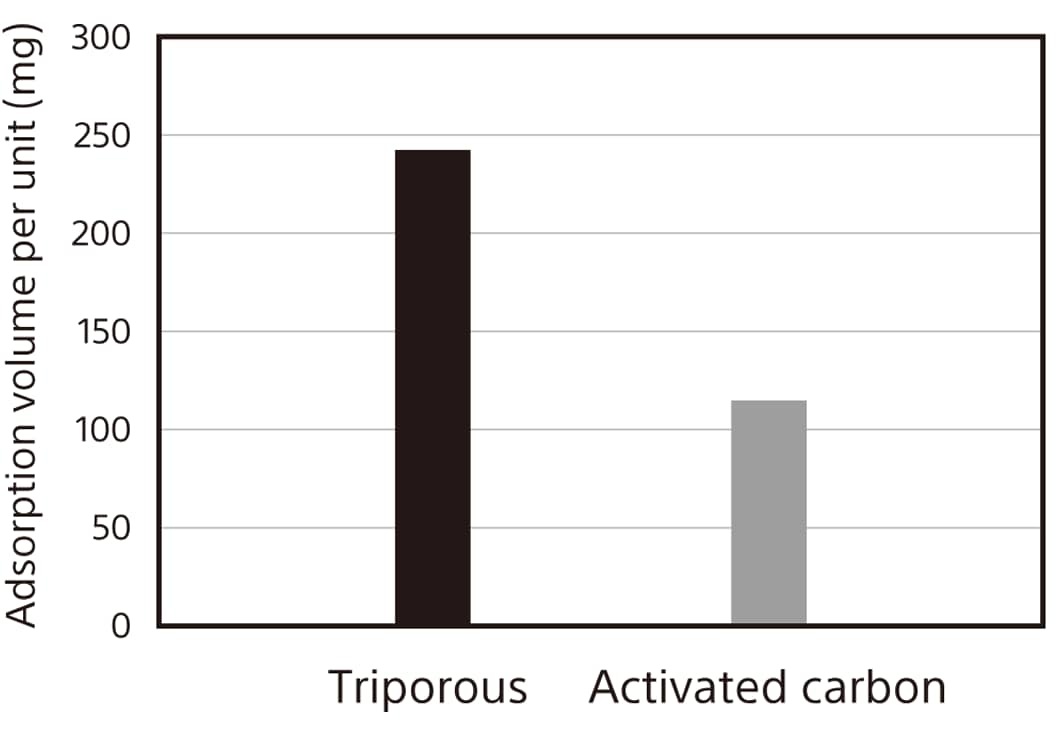

Comparison of adsorption volume per unit of ammonia gas for Triporous and coconuts shell based activated carbon

A comparison of the adsorption volume per unit mass of ammonia shows that Triporous deodorizes very effectively in a short time$2014approximately six times better than activated carbon.

Comparison of adsorption volume per unit of methylene blue for Triporous and coconuts shell based activated carbon

Even for adsorption of a pigment (methylene blue) in aqueous solution, Triporous adsorbs approximately twice as fast as activated carbon.

Adsorbs Organic Substances of Various Sizes

Adsorbs over twice as much high-molecular weight

organic pigments and 3 to 8 times more proteins

than conventional activated carbon*2.

Also adsorbs viruses and bacteria

Since Triporous is composed of a mix of 2-nm micropores, 2 to 50-nm mesopores, and approximately 1-$00B5m macropores,

it is capable of adsorbing large quantities of organic substances of various size.

For example, high-molecular weight organic compounds, which tend to cause a problem in industrial water treatment,

were adsorbed about twice in volume by Triporous compared to activated carbon.

It is also far more effective in treating proteins which are difficult to adsorb with activated carbon.

Triporous could achieve approximately three to eight times greater adsorption.

Moreover, Triporous eliminates over 99% of viruses and bacteria, so it has the potential to make a substantial contribution

to the water purification systems of emerging countries and to water recycling systems in arid regions.

- *2 Activated carbon made from coconut shell

Adsorption of large molecular weight dye (Black 5)

Triporous is approximately twice as adsorptive as activated carbon based on adsorption per gram of a high-molecular-weight pigment (Black5).

Adsorption of protein (fel d 1)

Triporous is approximately eight times more effective than activated carbon in adsorbing protein (fel d 1)(measured by Institute of Tokyo Environmental Allergen, Test No:T1706032 )

Adsorption of virus

Whereas activated carbon is almost completely ineffective against viruses, Triporous adsorbs them in the water.

(measured by Bio medical science association, Test No: BMR27-14)

Large Chemical Loading Capacity

extends life expectancy for more than twice of activated carbon when used in air purifiers and in industrial filters

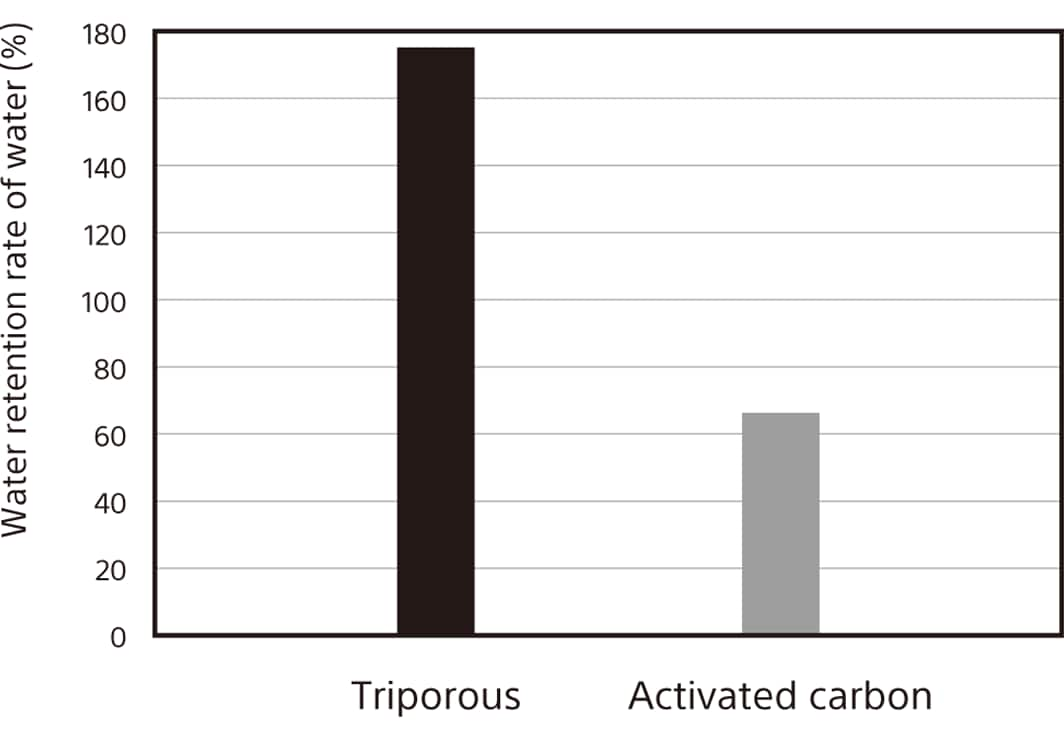

The large volume of tiny cavities in the macropores and mesopores of Triporous give it a high water retention rate.

This means that it can be impregnated with more of a chemical agent or catalyst than conventional activated carbon.

Currently, industrial filters, household air purifiers, and similar devices are made using activated carbon impregnated with a particular chemical agent,

depending on the application.

Since Triporous contains a large volume of tiny cavities in its macropores and mesopores, and can therefore be impregnated with a greater amount of chemical agent than conventional activated carbon, Triporous filters can be made to last more than twice as long as activated carbon-based filters.

Comparison of water retention rate: Triporous vs. activated carbon

Triporous has more than twice the water retention rate of activated carbon.

Considering its technical characteristics, applications are possible across a wide variety of fields and industries, including apparel (deodorant fibers, etc.), water purification (water filters, etc.), air-conditioning (air filters, etc.), and even health care (cleansing agents, etc.).

Please see below for details.